Dyson – PencilVac™: The evening clean-up routine, done quickly and conveniently

(Photo credit: EDB Singapore)

Source: EDB Singapore

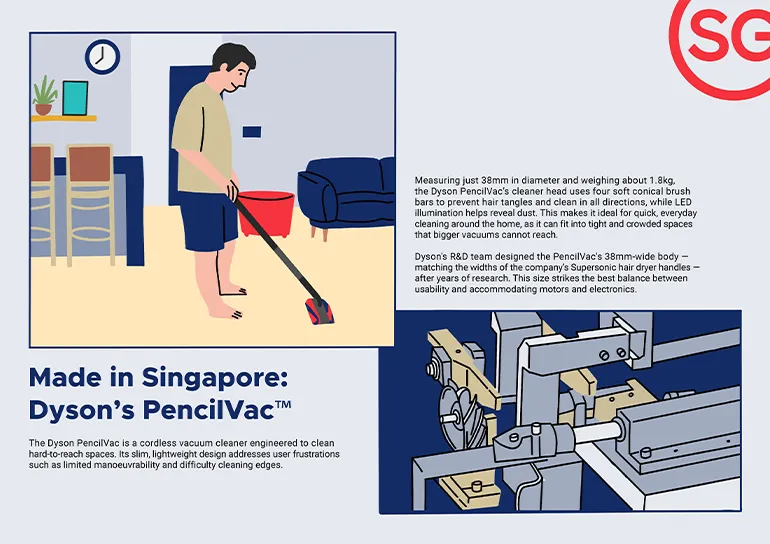

Dyson’s PencilVac – the latest cordless vacuum cleaner in the consumer electronics company’s range – is a slim and lightweight vacuum designed to address common user frustrations, such as limited manoeuvrability and cleaning hard-to-reach spaces and edges. The main challenge in its development was fitting all the components into a compact 38mm body frame. The task entailed not just miniaturising each part, but redesigning them for greater efficiency without compromising performance.

At the core of the PencilVac is the Hyperdymium™ 140k motor, Dyson’s smallest and fastest motor to date. Developed and manufactured in Singapore, this motor powers the vacuum’s high performance in an ultra-compact form. The PencilVac is also Dyson’s first connected cordless vacuum, pairing with an app to provide users with real-time battery and maintenance alerts. The software and user interface were developed by the company’s software team in Singapore.

Since establishing its global headquarters in Singapore in 2019, Dyson has built a significant ecosystem encompassing engineering, supply chain, finance, procurement, IT, and manufacturing operations. Dyson operates nearly 50 research laboratories in total across its Singapore campuses. These laboratories explore diverse fields that range from software and machine learning, to robotics, sensing, and vision systems.

Dyson’s Singapore Advanced Manufacturing (SAM) facility, which houses seven fully automated production lines that produce one motor every two seconds, plays a key role in the company’s operations. The factory employs over 300 robots to assemble motors with precision.

Singapore remains the centre of Dyson’s innovation efforts, as the home to its full range of engineering capabilities that drive the development of new technologies. The company employs over 2,000 staff in Singapore, half of whom are engineers. These engineers have played a key role in developing the PencilVac and the Hyperdymium 140k motor, which has built on the first-generation motor made in Singapore in 2004. Dyson marked a significant milestone of having produced 100 million motors – powering its vacuum cleaners, air purifiers, and hair dryers – in Singapore by the end of 2025.

“Singapore is a great place to recruit and have good quality engineers. So it’s a great place for us to be as an engineering [and] technology company, to be headquartered here, have access to the talent here, [together with a] very supportive government.”

James Dyson

Founder and Chairman

Dyson

From Singapore to the World – six innovative products by global leaders from Dyson to HP